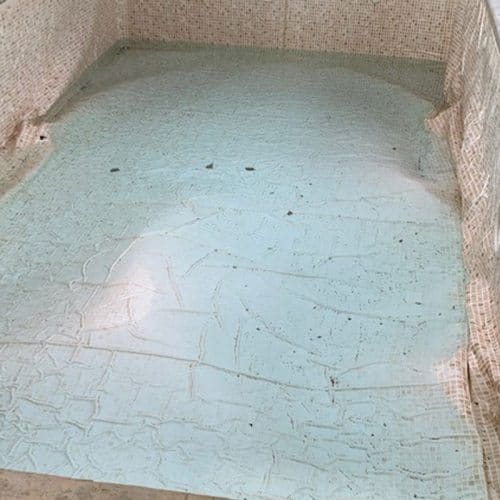

Lovett Pools were called out to a house in Leicester to assess a clients’ pool to see why the liner was no longer looking as it should.

It was apparent on visiting the pool, that it was overfilled and overheated which caused the liner to wrinkle and the colour to fade. The issue with liner pools is that once the colour has faded or the liner has lost its shape it is almost impossible for the pool to look brand new again. We discuss various options with the client and it was decided a new liner was required.

As the client instructed us to replace the liner our initial call out fee was deducted from our replacement liner invoice.

We drained down the pool, removed & disposed of the old liner and pressure tested the pipework to check there was no leaks in the pipework.

At Lovett Pools, we pressure test all pipework before fitting any new liner as a matter of course to ensure there will be no issues with water loss or leaks once the new liner has been installed. If any leaks are found, we always discuss a plan of action and provide a quote to fix the leaks prior to carrying out any further works.

Once the pool was drained down, the pool was measured for anew liner and the client was provided with various liner patterns and colour options.

The liner is usually made and delivered within 5 days of the pool being measured and fitted over a period of 2-3days.

The new patterned liner was fitted and the pool filled up and commissioned ready for use and the client was very happy with the difference in having the new blue liner fitted.

We also provided the client with some maintenance advice to avoid the new liner being worn out prematurely and also offered our maintenance service package if required.